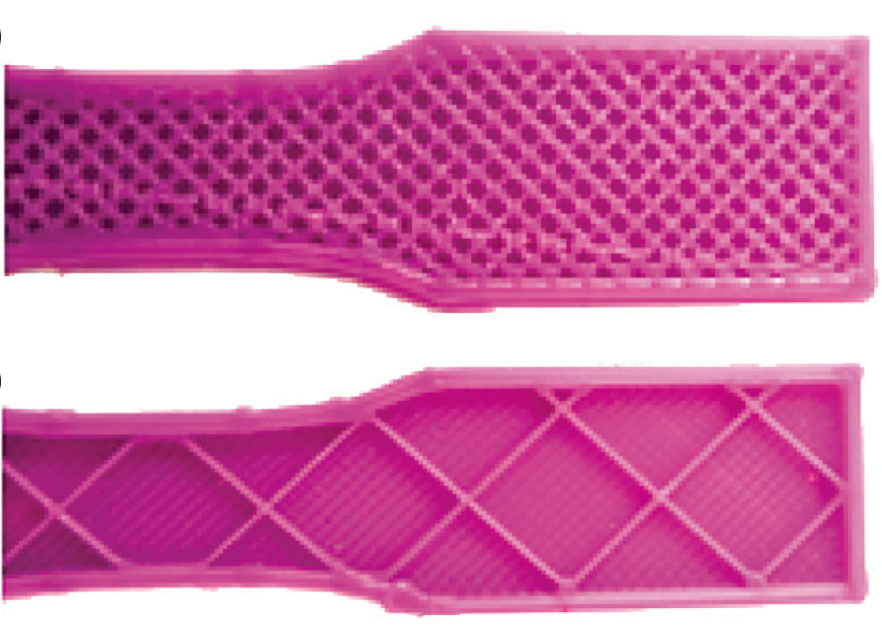

Tests show that 3D-printed polycarbonate with and without PIN FRs show different fire performance results than granules. 3D-printable polycarbonate (Covestro) was tested with two different transparency-compatible PIN FR masterbatches (Gabriel-Chemie) then extruded to 1.75 mm diameter 3D-printing strands. Fire testing was carried out on both the unprinted strands (cut to granules) and on a 3D-printed sample (railway LED light component), printed by FDM (fused deposition modelling), nozzle temperature 300°C. Neat polycarbonate achieved UL94-V0 at 25% but only V1 at 50% printing density. The PIN FRs reduced peak heat release rate for the unprinted polycarbonate by -15% to -19%, but after printing, the PIN-FR-polycarbonate failed UL94 or achieved only V1 at low printing density, but could (in some cases) achieve V0 at printing density 50% – the reverse of the neat polycarbonate. The authors conclude that print parameters and FR selection require specific solutions for 3D-printing.

“Influence of 3D-Printing on the Flammability Properties of Railway Applications Using Polycarbonate (PC) and Polylactic acid (PLA)”, D. Hohenwarter et al., Problemy Kolejnictwa, Issue 187 (June 2020), pp. 99-107, https://doi.org/10.36137/1874E