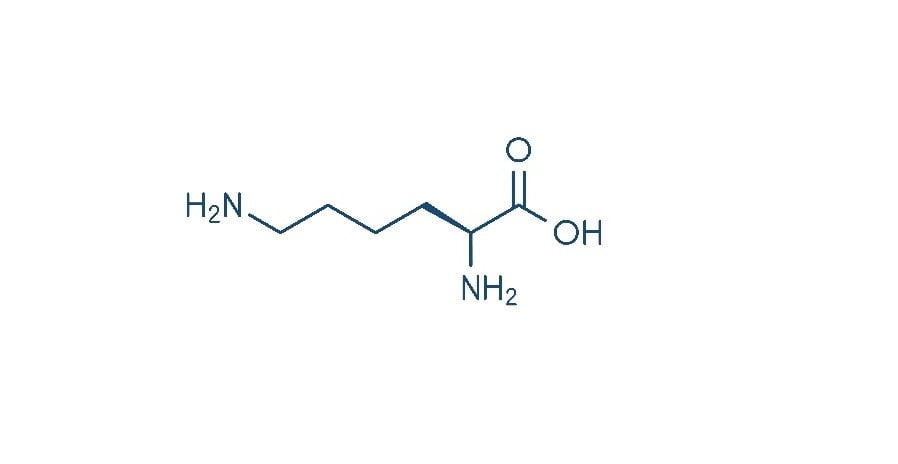

The natural molecule polylysine, reacted with phosphoric acid, provides a durable PIN FR for cotton fabrics. The polypeptide ε polylysine can be produced by natural fermentation or by a condensation reaction of the biological amino acid lysine, and is used as a food additive. Its large number of free amino groups enables binding of over 10% w/w phosphorus after reaction with glycerol and phosphoric acid. It contains nitrogen which may also contribute FR effect. Cotton fabric (124 g/m2) was activated using sodium hydroxide, then soaked in the phosphorylated polylysine (10 minutes @ 95°C) then cured @ 185°C, achieving 20% load to cotton w/w. This treatment reduced after flame and after-glow times to zero and reduced pHRR to 7% of untreated cotton. After 50 standard wash cycles, after-flame and after-glow were still zero, and pHRR was still only 14% of untreated cotton. Whiteness and mechanical properties of the cotton were well retained after treatment. The authors suggest that the small loss of fire performance with washing is due to replacement of ammonia groups in the polylysine by metals from the wash liquor.

“A novel e-polylysine-derived durable phosphorus-nitrogen based flame retardant for cotton fabrics”, F. Xu et al., Cellulose 2021 https://doi.org/10.1007/s10570-021-03714-z