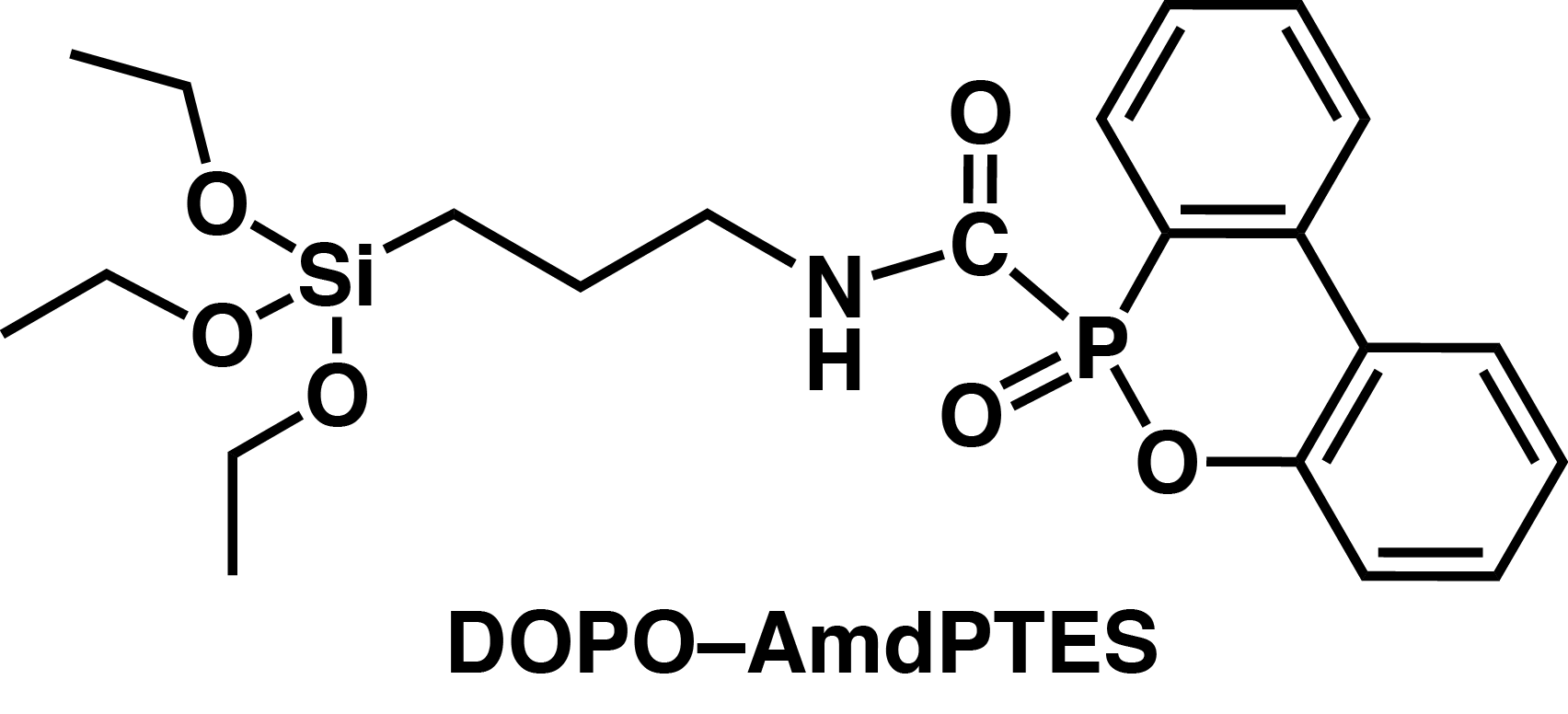

A new N P Si compound was synthesised and showed fire performance and semi-durability on cotton. The new compound, DOPO-AmdPTES, was compared to and showed better performance than similar DOPO-oxysilane (DOPO-ETES, see Vasiljević et al. 2015). Both compounds were applied to cotton fabric by sol-gel application and pad-dry-cure finishing. The curing at 130°C resulted in a silane polymer network on the cotton surface. DOPO-AmdPTES was synthesised by reacting DOPO* with the commercially-available nitrogen – silane compound 3-isocyanatopropyltriethoxysilane (ICPTES). The treatment of the cotton resulted in 3.3% P and 5.5% Si on the cotton surface and a total c. 27% DOPO-AmdPTES w/w loading of the cotton and led the cotton to be self-extinguishing, with PHHR (peak heat release rate) 62% lower than untreated cotton and LOI (limiting oxygen index) 56% higher. Self-extinguishing is maintained after ten wash cycles, showing wash semi-durability, probably due to the hydrophobic properties of the DOPO-AmdPTES, covalent bonding of free silanol groups to cotton during curing and hydrogen bonding of amido groups. The flame retardancy is considered to be mainly due to catalysis of char formation and to a gas-phase dilution effect. The weaker P-bond, compared to DOPO-ETES, resulting in more rapid degradation in fire, probably explains the better fire performance.

* DOPO = 9,10-Dihydro-9-oxa-10-phosphaphenanthrene-10-oxide

“Flame‑retardant finishing of cotton fabrics using DOPO functionalized alkoxy‑ and amido alkoxysilane”, W. Ali, T. Mayer-Gall et al., Cellulose 2023 https://doi.org/10.1007/s10570-022-05033-3