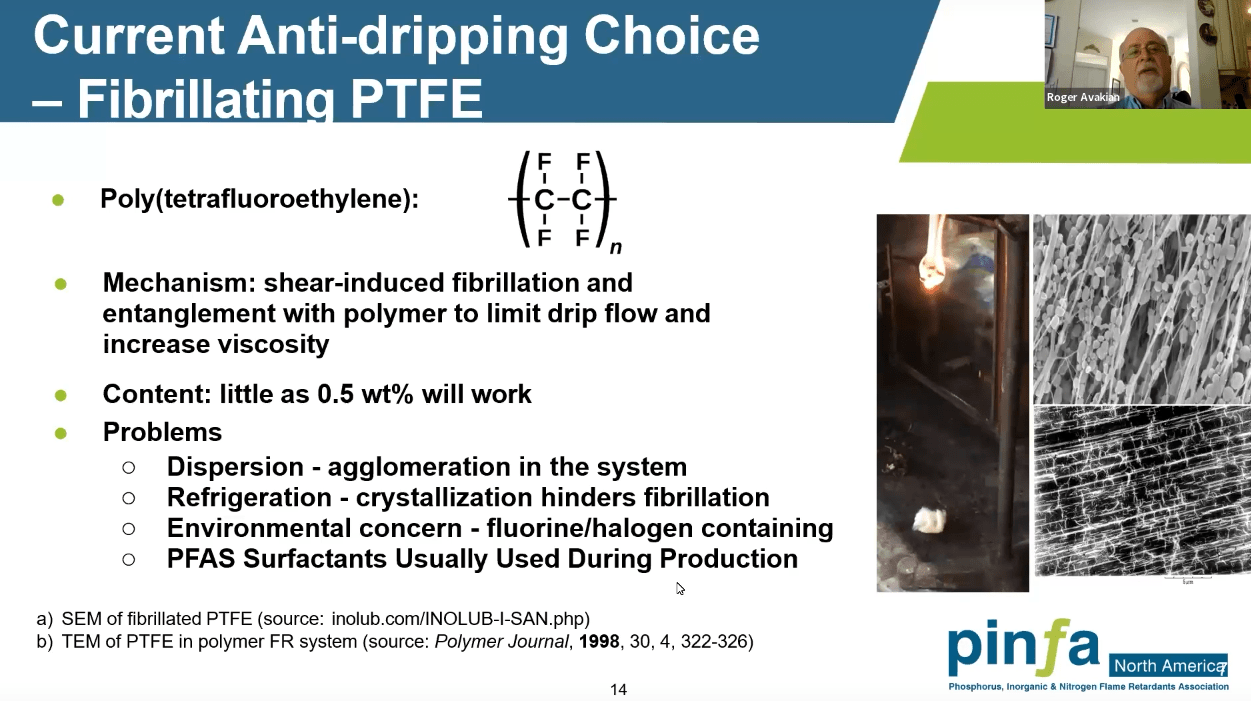

pinfa North America webinar outlines development in non-PFAS drip suppressants for polymer fire safety, with Roger Avakian, polymer formulation expert. In fire, polymers melt and break down to smaller molecules, causing dripping which risks spreading fire to other materials. Therefore, flaming dripping causes failure of fire tests such as UL 94 V-0. Fibrillated PTFE, a PFAS (polyfluoroalkyl substance) is today widely used to prevent melt-dripping, usually at low loading (0.5 – 2%). In heat, the fibrils contract, contracting the polymer and inhibiting melt-dripping. However, given the expected regulatory restriction of PFAS (see pinfa Newsletter n°148), downstream users are actively looking for non-halogenated, non-PFAS fire safety solutions.

Non-halogenated non-drip solutions, for use in combination with PIN flame retardants, are today available in some polymers and are being widely researched. These can act by different mechanisms including increasing polymer melt viscosity (e.g. minerals), creating structural char layers which physically prevent dripping by ceramified or branched char (e.g. silicones, treated minerals, fibrous minerals), or by chemically reacting or catalysing polymer cross-linking in fire (e.g. zinc or boron compounds, carboxylic acids) – or by combinations of these mechanisms. Active research is also underway into other possible solutions such as bio-based or nano-materials (e.g. corn starch, glass flakes …). The webinar outlined each of these different approaches: mode of action, state of development, solutions on the market, and discussed applicability to different polymers.

Watch online the pinfa-NA webinar of 6 December 2023 “Drip suppressants: a critical current ingredient and unmet market need” https://www.pinfa-na.org/presented-webinars