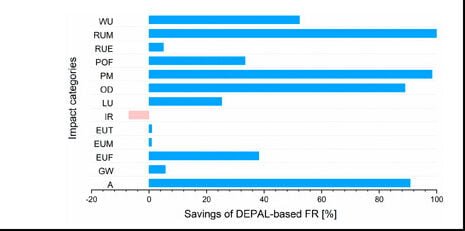

LCA comparison concludes that DEPAL* (PIN FR) has slightly lower carbon footprint and lower environmental impacts than brominated FR+ATO** in glass-fibre reinforced polyamide 6-6 for electric vehicles and electronics applications, where fire safety is required. Differences were particularly marked for consumption of mineral resources, ozone depletion, particulate emissions and acidification. The authors note that energy consumption needed to produce P4, essential for DEPAL synthesis, is significant, and the carbon footprint calculation assumed 42% renewable energy (hydro). The DEPAL carbon footprint could be improved by higher use of renewable energy in P4 production. Both carbon footprint and certain environmental impacts (in particular mineral resources) for the BrFR-ATO case were largely due to the ATO. Overall, using recommended normalisation factors (excluding toxicity, for which the DEPAL case also showed lower impact), the aggregated environmental footprint of the DEPAL fire-protected reinforced polymer is 0.72/FU, whereas that for the BrFR-ATO case is 250.

* DEPAL = aluminium diethyl phosphinate.

** Comparison was to brominated polystyrene plus ATO (antimony trioxide).

“Toward Sustainable Fire Safety: Life Cycle Assessment of Phosphinate-Based and Brominated Flame Retardants in E‑Mobility and Electronic Devices”, D. Maga, V. Aryan, A. Beard, ACS Sustainable Chem. Eng. 2024, 12, 3652−3658, https://doi.org/10.1021/acssuschemeng.3c07096

Study carried out by Fraunhofer UMSICHT research institute, Germany, funded by pinfa member Clariant.