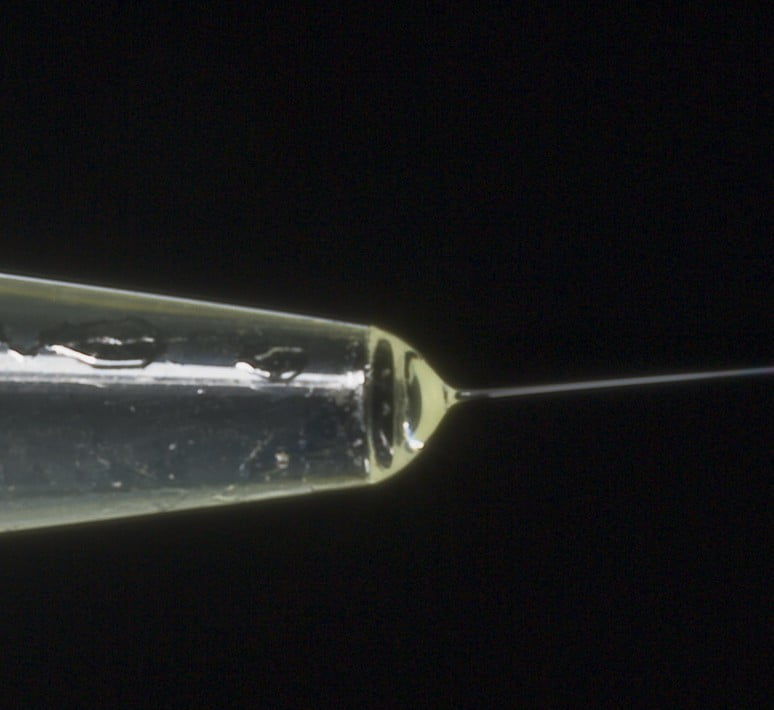

Electrospinning offers routes to develop new FR fibre solutions with improved mechanical properties, e.g. with multiple materials. Electrospinning is a known process for producing continuous polymer fibres, with diameters from 100 nm to 10 µm, or fibre mats. Injection under high voltage induces polymer polarity resulting in highly stretched flow. FRs can be effectively dispersed into the fibres as micro- or nano-particles, either in the bulk polymer or in the surface layer. Some 25 examples from literature are shown, covering a range of polymers (polyamide, polyimide, cellulose and others). Applications include membranes, filters, protective clothing and fabrics. All the FRs in the identified applications are PIN, including minerals, nano-carbons and P-based PIN FRs, for example for safer membranes for lithium-ion batteries. The authors suggest significant development possibilities for miniaturisation, nano fibre integration, improved FR dispersion, polymer surface heat-shielding.

“Electrospinning for developing flame retardant polymer materials: Current status and future perspectives”, H. Vahabi et al., Polymer 217 (2021) 123466, https://doi.org/10.1016/j.polymer.2021.123466

Photograph by Robert Lamberts at The New Zealand Institute for Plant and Food Research Ltd