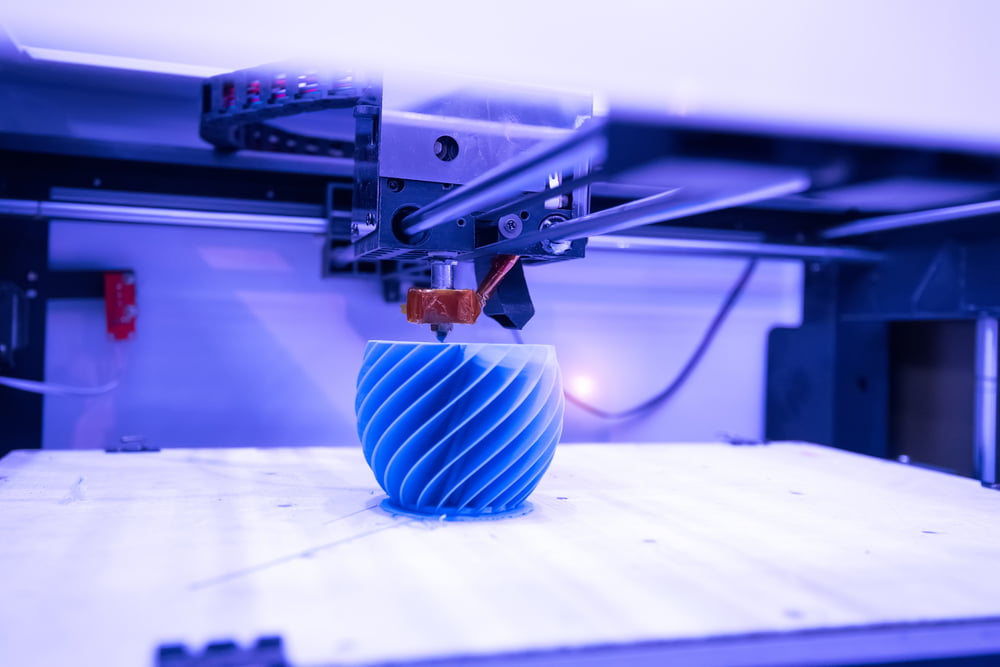

3D printing enables new approaches to flame retardancy, such as surface layers or enclosure of FRs in structural voids. This review summarises different current FR solutions for different polymers and outlines AM (additive manufacturing) technologies: stereolithography (SLA), digital light processing, multijet/polyjet, selective laser sintering (SLS), selective heat sintering (SHS), fused deposition or filament fabrication, laminated object manufacturing. A range of polymer FR formulations are today available for 3D printing: 14 different companies’ products are cited (all non-halogenated except one), covering polyamides, ABS, PLA and specialist polymers. Instead of including FRs in the bulk polymer, 3D printing enables other fire retardancy approaches, in particular including the FR only or at higher loadings in the article surface, or building the article with structural micro-voids containing concentrated FRs. These strategies can avoid impacts of FRs on printed polymer properties. These new approaches may require new fire standards and testing methods.

“Flame retardant polymer materials: An update and the future for 3D printing developments”, H. Vahabi et al., Materials Science & Engineering R 144 (2021) 100604, https://doi.org/10.1016/j.mser.2020.100604